Introduction:

In the fast-paced and ever-evolving landscape of the United Arab Emirates (UAE), businesses are constantly seeking innovative solutions to enhance efficiency and productivity. One crucial aspect that plays a pivotal role in achieving these goals is the organization and utilization of space within industrial settings. Industrial Heavy Duty Racking System have emerged as indispensable tools for businesses across the UAE, offering a systematic approach to storage, inventory management, and space optimization.

Maximizing Vertical Space:

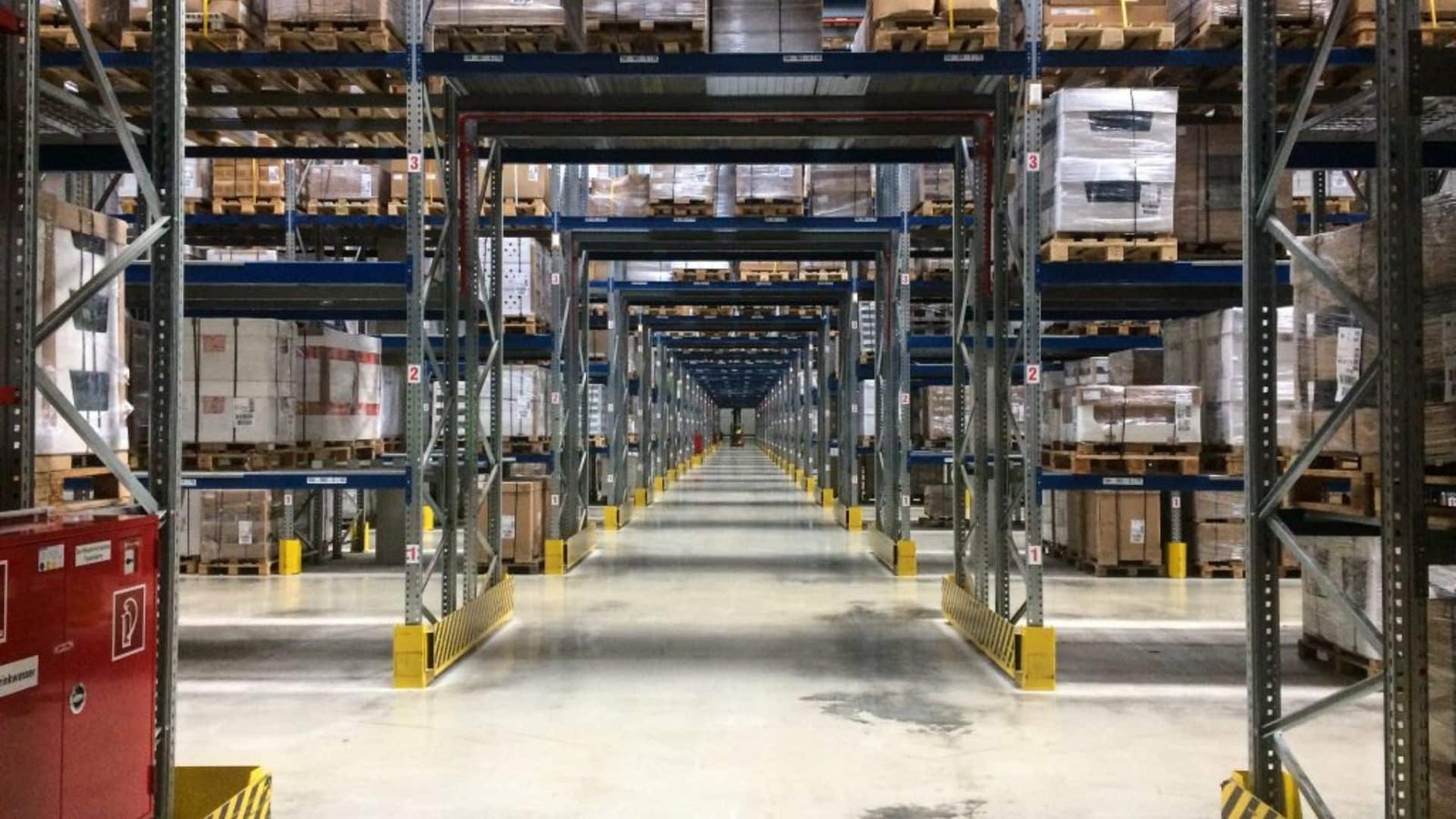

Industrial racking systems are designed to make the most of vertical space within warehouses and manufacturing facilities. In a region where land is at a premium, utilizing vertical space becomes imperative. These systems consist of sturdy shelves and racks that can be stacked vertically, allowing businesses to store goods and materials in a space-efficient manner. This not only helps in maximizing storage capacity but also contributes to a more organized and streamlined workflow.

Customized Solutions for Varied Needs:

One of the key advantages of industrial racking systems is their versatility. Businesses in the UAE operate across diverse industries, each with unique storage requirements. Whether it’s automotive parts, electronic components, or retail merchandise, racking systems come in various configurations to accommodate different sizes and types of goods. The ability to customize these systems ensures that businesses can tailor their storage solutions to meet specific needs, promoting better organization and accessibility.

Improved Inventory Management:

Efficient inventory management is critical for businesses to meet customer demands and minimize operational disruptions. Industrial racking systems provide a structured approach to organizing inventory, making it easier for businesses to track and manage stock levels. With clear labeling and easy accessibility, employees can quickly locate and retrieve items, reducing the risk of errors and delays in fulfilling orders. This streamlined inventory management contributes to overall business efficiency.

Enhanced Safety Standards:

Safety is paramount in any industrial setting, and industrial racking systems are designed with this in mind. These systems are built to withstand heavy loads and are equipped with safety features such as beam locks and secure anchoring. This not only protects employees and goods but also ensures the longevity of the racking system. In the UAE, where stringent safety standards are enforced, investing in reliable industrial racking solutions becomes a strategic move for businesses aiming to maintain a safe working environment.

Adaptability to Automation:

With the growing emphasis on automation in the UAE’s industrial landscape, racking systems play a crucial role in supporting these advancements. Automated storage and retrieval systems (AS/RS) can be seamlessly integrated with industrial racking, allowing for efficient and precise material handling. This integration not only optimizes space utilization but also contributes to the overall modernization and competitiveness of businesses in the UAE.

Conclusion:

In conclusion, industrial racking systems serve as integral components in the quest for better organization and space utilization within UAE businesses. Their ability to maximize vertical space, provide customized solutions, improve inventory management, enhance safety standards, and adapt to automation reflects their versatility and importance in the dynamic business environment of the UAE. As businesses continue to evolve and strive for operational excellence, investing in efficient storage solutions like industrial racking systems remains a strategic imperative for sustained success in the region.